Product Description

Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer PIN MH Rigid NM Jaw Gear transmission industrial gearbox manufacture parts pric F Flexible Coupling

YOXz is a coincidence machine with moving wheel which is in the output point of the coincidence machine and is connected with elastic axle connecting machine (plum CHINAMFG type elastic axle connecting machine or elastic pillar axle-connecting machine or even the axle-connecting machine designated by customers). Usually there are 3 connection types.

YOXz is inner wheel driver which has tight structure and the smallest axle size.The fittings of YOXz have a wide usage, simple structure and the size of it has basically be unified in the trade.The connection style of YOXz is that the axle size of it is longer but it is unnecessary to move the electromotive machine and decelerating machine. Only demolish the weak pillar and connected spiral bolt can unload the coincidence machine so it is extreme convenient. Customer must offer the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The wheel size (Dz Lz C) in the table is just for reference, the actual size is decided by customers.

Main Features

1. Applies to flexible drive shaft ,allowing a larger axial radial displacement and displacement.

2.Has a simple structure,easy maintenance .

3.Disassembly easy

4.low noise

5.Transmission efficiency loss,long useful working life.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | – |

| Torque: | – |

| Bore Diameter: | – |

| Speed: | – |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can Spacer Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, spacer couplings can be used in both horizontal and vertical shaft arrangements. The design of spacer couplings allows them to accommodate misalignment between shafts and transmit torque while maintaining a reliable connection. Here’s how they can be used in each configuration:

1. Horizontal Shaft Arrangements:

In horizontal shaft arrangements, the spacer coupling is installed between two shafts that are aligned on the same horizontal plane. The spacer coupling connects the two shaft ends and compensates for any radial, axial, or angular misalignment between them. This configuration is commonly used in various industrial applications, including conveyor systems, pumps, compressors, and fans.

2. Vertical Shaft Arrangements:

In vertical shaft arrangements, the spacer coupling is used to connect two shafts that are aligned on a vertical plane. This configuration is often found in applications where space is limited, and the mechanical equipment is stacked vertically. Spacer couplings in vertical arrangements can handle both the torque and the weight of the rotating components. The design should account for the additional force due to gravity acting on the connected equipment.

Advantages of Using Spacer Couplings:

– Spacer couplings provide flexibility and ease of installation in both horizontal and vertical shaft arrangements.

– They accommodate misalignment, reducing the risk of premature wear and increasing the lifespan of the connected equipment.

– Spacer couplings are available in various designs and materials, making them suitable for a wide range of applications.

– They allow for easy maintenance and replacement of components without the need to disassemble the entire system.

Note: When selecting a spacer coupling for a specific application, it is essential to consider factors such as torque requirements, operating conditions, and the level of misalignment expected in the system. Following the manufacturer’s guidelines for installation, maintenance, and usage is crucial to ensure the spacer coupling’s optimal performance and longevity in both horizontal and vertical shaft arrangements.

Use of Spacer Couplings for Motor-to-Shaft and Shaft-to-Shaft Connections

Yes, spacer couplings can be used for both motor-to-shaft and shaft-to-shaft connections in various mechanical systems and power transmission applications. The versatility of spacer couplings allows them to accommodate different types of connections between rotating machinery and shafts.

1. Motor-to-Shaft Connections:

In motor-to-shaft connections, a motor is connected to a driven shaft or component. Spacer couplings can be utilized to bridge the gap between the motor and the driven shaft while maintaining the required alignment. These couplings help transmit torque from the motor to the driven shaft efficiently, ensuring smooth power transmission. They also compensate for any misalignment between the motor and the driven shaft, reducing the risk of mechanical stress and vibration-related issues.

2. Shaft-to-Shaft Connections:

For shaft-to-shaft connections, where two shafts need to be connected together, spacer couplings provide a flexible and reliable solution. Spacer couplings can handle angular, parallel, and axial misalignment between the shafts, allowing them to operate smoothly even when there are slight deviations in alignment. This capability helps prevent excessive wear and premature failure of equipment components.

Whether in motor-to-shaft or shaft-to-shaft connections, spacer couplings play a vital role in enhancing the reliability and efficiency of power transmission systems. They help protect connected equipment from shock loads, vibrations, and misalignment, ultimately contributing to extended service life and reduced maintenance requirements.

It is essential to select the appropriate type and size of spacer coupling based on the specific application requirements, including torque capacity, operating speed, shaft size, and environmental conditions. Proper installation and alignment of the spacer coupling are crucial to ensure optimal performance and reliability of the connected equipment.

editor by CX 2024-05-14

China manufacturer Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer Pin Mh Rigid Nm Jaw Gear Transmission Industrial Gearbox Manufacture Parts Pric F Flexible Coupling

Product Description

Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer PIN MH Rigid NM Jaw Gear transmission industrial gearbox manufacture parts pric F Flexible Coupling

YOXz is a coincidence machine with moving wheel which is in the output point of the coincidence machine and is connected with elastic axle connecting machine (plum CHINAMFG type elastic axle connecting machine or elastic pillar axle-connecting machine or even the axle-connecting machine designated by customers). Usually there are 3 connection types.

YOXz is inner wheel driver which has tight structure and the smallest axle size.The fittings of YOXz have a wide usage, simple structure and the size of it has basically be unified in the trade.The connection style of YOXz is that the axle size of it is longer but it is unnecessary to move the electromotive machine and decelerating machine. Only demolish the weak pillar and connected spiral bolt can unload the coincidence machine so it is extreme convenient. Customer must offer the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The wheel size (Dz Lz C) in the table is just for reference, the actual size is decided by customers.

Main Features

1. Applies to flexible drive shaft ,allowing a larger axial radial displacement and displacement.

2.Has a simple structure,easy maintenance .

3.Disassembly easy

4.low noise

5.Transmission efficiency loss,long useful working life.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | – |

| Torque: | – |

| Bore Diameter: | – |

| Speed: | – |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can Spacer Couplings Accommodate High Torque and High-Speed Applications?

Yes, spacer couplings are designed to accommodate both high torque and high-speed applications. These couplings are known for their ability to transmit torque efficiently between shafts and handle various operating conditions. The design and material selection of spacer couplings allow them to excel in demanding industrial settings. Here’s how they handle high torque and high-speed applications:

1. Torque Capacity: Spacer couplings are often constructed with robust materials such as steel or stainless steel, which provide high torque capacity. The coupling’s design and material properties allow it to transmit substantial amounts of torque without failure. In heavy-duty applications, where high torque is prevalent, spacer couplings are a preferred choice.

2. High-Speed Operation: Spacer couplings are also well-suited for high-speed applications. The design of the coupling ensures a secure connection between the shafts while maintaining balance during rotation. The coupling’s precise machining and balance prevent vibration and misalignment, allowing for smooth operation at high rotational speeds.

3. Torsional Stiffness: Spacer couplings have good torsional stiffness, meaning they resist twisting under torque. This characteristic is essential for high-speed applications, as it helps maintain accurate shaft synchronization and minimizes torsional vibrations.

4. Customization: Manufacturers offer various spacer coupling designs and sizes to cater to specific torque and speed requirements. Depending on the application’s demands, users can select spacer couplings with the appropriate torque and speed ratings.

5. Maintenance: Proper maintenance is essential for ensuring that spacer couplings continue to handle high torque and high-speed applications effectively. Regular inspections, lubrication, and alignment checks can help identify and address potential issues before they escalate into problems.

When choosing a spacer coupling for high torque and high-speed applications, it is crucial to consider factors like the application’s torque and speed requirements, environmental conditions, and the coupling’s material and design specifications. Proper selection and installation of the spacer coupling contribute to the reliable and efficient performance of the machinery.

What Role Does a Spacer Coupling Play in Reducing Downtime and Maintenance Costs?

A spacer coupling plays a crucial role in reducing downtime and maintenance costs in rotating machinery by offering the following benefits:

1. Misalignment Compensation: Rotating equipment is subject to various types of misalignment during operation, which can lead to premature wear and failure of components. Spacer couplings can accommodate angular, parallel, and axial misalignment between shafts, which helps minimize the stress on the connected equipment. By reducing the impact of misalignment, spacer couplings contribute to extending the service life of the machinery and its components.

2. Vibration Damping: Vibrations in rotating machinery can lead to increased wear, fatigue, and reduced efficiency. Spacer couplings often include flexible elements made of elastomeric materials that act as vibration dampers. These elements absorb and dissipate vibration energy, reducing the transmission of harmful vibrations to the connected equipment. As a result, the machinery operates more smoothly and experiences less stress, leading to lower maintenance requirements.

3. Shock Load Absorption: During the operation of machinery, sudden shock loads may occur due to starting or stopping processes or external impacts. Spacer couplings with elastomeric or metallic flexible elements can absorb and cushion these shock loads, protecting the connected equipment from damage. By mitigating the effects of shock loads, spacer couplings contribute to the reliability and longevity of the machinery.

4. Easy Maintenance and Replacement: Spacer couplings are designed for ease of maintenance. In the event of a failure or wear of the flexible element, the coupling can be easily disassembled and the damaged component replaced, reducing downtime. The modular design of spacer couplings simplifies the maintenance process, helping to minimize the time required for repairs and reducing associated maintenance costs.

5. Corrosion Resistance: Many spacer couplings are manufactured using materials with excellent corrosion resistance, such as stainless steel or coated alloys. This corrosion resistance extends the service life of the coupling and reduces the need for frequent replacements or maintenance due to corrosion-related issues.

6. Reliability and Dependability: Spacer couplings are known for their robustness and reliability. When properly selected, installed, and maintained, they provide a dependable means of power transmission. The reduction in unplanned downtime due to coupling failure contributes to overall operational efficiency and lower maintenance costs.

In summary, spacer couplings help reduce downtime and maintenance costs in rotating machinery by accommodating misalignment, damping vibrations, absorbing shock loads, and offering ease of maintenance. Their reliability and ability to protect connected equipment contribute to improved operational efficiency and longer service life of the machinery, leading to cost savings over time.

editor by CX 2024-04-22

China best Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer Pin Mh Rigid Nm Jaw Gear Transmission Industrial Gearbox Manufacture Parts Pric F Flexible Coupling

Product Description

Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer PIN MH Rigid NM Jaw Gear transmission industrial gearbox manufacture parts pric F Flexible Coupling

YOXz is a coincidence machine with moving wheel which is in the output point of the coincidence machine and is connected with elastic axle connecting machine (plum CHINAMFG type elastic axle connecting machine or elastic pillar axle-connecting machine or even the axle-connecting machine designated by customers). Usually there are 3 connection types.

YOXz is inner wheel driver which has tight structure and the smallest axle size.The fittings of YOXz have a wide usage, simple structure and the size of it has basically be unified in the trade.The connection style of YOXz is that the axle size of it is longer but it is unnecessary to move the electromotive machine and decelerating machine. Only demolish the weak pillar and connected spiral bolt can unload the coincidence machine so it is extreme convenient. Customer must offer the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The wheel size (Dz Lz C) in the table is just for reference, the actual size is decided by customers.

Main Features

1. Applies to flexible drive shaft ,allowing a larger axial radial displacement and displacement.

2.Has a simple structure,easy maintenance .

3.Disassembly easy

4.low noise

5.Transmission efficiency loss,long useful working life.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | – |

| Torque: | – |

| Bore Diameter: | – |

| Speed: | – |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

What Are the Maintenance Requirements for Spacer Couplings?

Spacer couplings are relatively low-maintenance compared to some other types of couplings. However, regular inspections and preventive measures are essential to ensure their optimal performance and longevity. Here are the key maintenance requirements for spacer couplings:

1. Visual Inspections: Regularly inspect the spacer coupling and its components for signs of wear, damage, or misalignment. Look for any visible cracks, corrosion, or deformation.

2. Lubrication: Some spacer couplings may require periodic lubrication, especially if they have rolling elements such as bearings or if the coupling design necessitates lubrication. Follow the manufacturer’s guidelines for the appropriate lubrication intervals and type of lubricant to use.

3. Alignment Checks: Proper alignment between the connected shafts is crucial for spacer coupling performance. Periodically check and adjust the alignment to ensure that the coupling operates smoothly and efficiently. Misalignment can lead to premature wear and failure of the coupling.

4. Bolt Tightening: Check and tighten the coupling bolts regularly to maintain the desired clamping force. Loose bolts can cause vibrations and compromise the integrity of the coupling connection.

5. Environmental Considerations: In harsh or corrosive environments, pay close attention to the effects of the operating conditions on the coupling. Consider using corrosion-resistant materials or protective coatings to prolong the coupling’s life.

6. Replacement of Worn Components: If any components of the spacer coupling show signs of wear or damage beyond acceptable limits, replace them promptly. This includes components like the spacer, bolts, and locking devices.

7. Regular Maintenance Schedule: Develop a regular maintenance schedule based on the coupling manufacturer’s recommendations and the specific operating conditions of the machinery. A well-maintained coupling can significantly extend the life of the connected equipment.

8. Consult Manufacturer Guidelines: Always refer to the manufacturer’s maintenance guidelines and recommendations. They will provide specific instructions on maintenance intervals and procedures for the particular spacer coupling model.

By following these maintenance practices, you can ensure that the spacer coupling remains in optimal condition, reduces the risk of unexpected failures, and contributes to the overall reliability and efficiency of the machinery it connects.

Factors to Consider When Choosing a Spacer Coupling for a Specific System

Choosing the right spacer coupling for a specific system requires careful consideration of various factors to ensure optimal performance and reliability. Here are the key factors to keep in mind:

1. Operating Conditions: Understand the operating conditions of the system where the spacer coupling will be used. Consider factors such as torque requirements, rotational speed, temperature range, and environmental conditions (e.g., corrosive, humid, or dusty environments).

2. Misalignment Compensation: Determine the type and magnitude of misalignment that the coupling needs to accommodate. Spacer couplings can handle angular, parallel, and axial misalignments to varying degrees, so selecting the appropriate coupling design is critical.

3. Shaft Sizes and Types: Ensure that the spacer coupling’s bore size matches the shaft diameters of the connected equipment. Additionally, consider whether the shafts are keyed, splined, or have other special features that may require customization of the coupling.

4. Coupling Material: The choice of material for the spacer coupling depends on the application’s requirements. Common materials include steel, stainless steel, aluminum, and various alloys. Consider factors such as strength, corrosion resistance, and temperature limits when selecting the material.

5. Torque and Speed Ratings: Determine the required torque and rotational speed ratings for the coupling based on the power transmission needs of the system. Select a coupling that can handle the specified torque and speed without exceeding its limits.

6. Spacer Length: The length of the spacer in the coupling affects the distance between connected equipment. Ensure that the chosen spacer length allows for proper clearance and alignment between the components.

7. Installation and Maintenance: Consider the ease of installation and maintenance requirements of the spacer coupling. Some couplings may require more frequent maintenance than others, which can impact overall system downtime.

8. Cost and Budget: Evaluate the cost of the spacer coupling and ensure that it fits within the project budget. While cost is a consideration, it is essential not to compromise on quality and performance for the sake of cost savings.

9. Industry Standards and Regulations: Ensure that the chosen spacer coupling complies with relevant industry standards and safety regulations. Adherence to these standards helps guarantee the coupling’s quality and suitability for the intended application.

10. Supplier and Support: Choose a reputable supplier with a track record of providing high-quality spacer couplings. A reliable supplier can offer technical support, assistance with selection, and post-purchase services if required.

By carefully considering these factors and evaluating the specific needs of the system, engineers and designers can select the most appropriate spacer coupling to ensure efficient power transmission, reduce wear on connected equipment, and enhance overall system performance and reliability.

editor by CX 2024-04-11

China supplier Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer Pin Mh Rigid Nm Jaw Gear Transmission Industrial Gearbox Manufacture Parts Pric F Flexible Coupling

Product Description

Couplings Fluid Flange Flexible HRC Chain Fenaflex Spacer PIN MH Rigid NM Jaw Gear transmission industrial gearbox manufacture parts pric F Flexible Coupling

YOXz is a coincidence machine with moving wheel which is in the output point of the coincidence machine and is connected with elastic axle connecting machine (plum CHINAMFG type elastic axle connecting machine or elastic pillar axle-connecting machine or even the axle-connecting machine designated by customers). Usually there are 3 connection types.

YOXz is inner wheel driver which has tight structure and the smallest axle size.The fittings of YOXz have a wide usage, simple structure and the size of it has basically be unified in the trade.The connection style of YOXz is that the axle size of it is longer but it is unnecessary to move the electromotive machine and decelerating machine. Only demolish the weak pillar and connected spiral bolt can unload the coincidence machine so it is extreme convenient. Customer must offer the size of electromotive machine axle (d1 L1) and decelerating machine axle (d2 L2). The wheel size (Dz Lz C) in the table is just for reference, the actual size is decided by customers.

Main Features

1. Applies to flexible drive shaft ,allowing a larger axial radial displacement and displacement.

2.Has a simple structure,easy maintenance .

3.Disassembly easy

4.low noise

5.Transmission efficiency loss,long useful working life.

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | – |

| Torque: | – |

| Bore Diameter: | – |

| Speed: | – |

| Structure: | Flexible |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

How Does a Spacer Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Spacer couplings play a vital role in protecting connected equipment from shock loads and vibrations in mechanical systems. They act as a buffer between the driving and driven components, absorbing and mitigating the impact of sudden shocks and vibrations. Here’s how spacer couplings provide this protection:

1. Dampening Effect: Spacer couplings are designed with flexible elements or materials that possess inherent damping properties. When subjected to shock loads or vibrations, these flexible elements absorb and dissipate the kinetic energy, reducing the impact on the connected equipment. This dampening effect helps prevent damage to delicate components and extends the equipment’s lifespan.

2. Misalignment Compensation: In addition to damping, spacer couplings can also accommodate certain degrees of angular, parallel, and axial misalignment between the shafts. When misalignment occurs, the coupling’s flexibility allows it to adjust slightly, reducing the transmitted forces to the connected equipment. By minimizing the effects of misalignment, spacer couplings help avoid excessive forces that could lead to shock loads and vibrations.

3. Vibration Isolation: Vibrations can be generated by various sources, including unbalanced loads, motor vibrations, and external factors. Spacer couplings, with their flexible elements, act as vibration isolators, preventing the propagation of vibrations from one shaft to the other. This isolation protects the connected equipment from experiencing detrimental vibrations that may lead to wear, fatigue, or failure.

4. Torsional Stiffness: While spacer couplings offer flexibility to absorb shock loads and vibrations, they also possess adequate torsional stiffness. This property helps maintain shaft alignment and synchronization during normal operation, reducing the risk of additional vibrations caused by misalignment or torsional forces.

5. Material Selection: Spacer couplings are often manufactured from materials with excellent fatigue and shock resistance properties, such as steel or aluminum alloys. The choice of materials ensures that the coupling can withstand repeated shock loads without experiencing premature fatigue or failure.

6. Redundancy and Reliability: In critical applications where shock loads and vibrations are common, some designs incorporate multiple flexible elements or redundancies to enhance the coupling’s reliability and capacity to handle extreme conditions.

Overall, spacer couplings are essential components in mechanical systems that require protection against shock loads and vibrations. Their ability to dampen, isolate, and compensate for misalignment helps maintain the health and longevity of connected equipment, ensuring smooth and reliable operation in various industrial settings.

How Does a Spacer Coupling Handle Angular, Parallel, and Axial Misalignment?

A spacer coupling is a type of flexible coupling that is designed to accommodate different types of misalignment between shafts. Here’s how it handles angular, parallel, and axial misalignment:

1. Angular Misalignment: Angular misalignment occurs when the axes of the two shafts are not parallel but intersect at a certain angle. A spacer coupling can handle angular misalignment by allowing the flexible element (such as an elastomeric or metallic component) to flex and bend when the shafts are not perfectly aligned. This bending action allows the coupling to compensate for the angular displacement between the shafts and transmit torque smoothly.

2. Parallel Misalignment: Parallel misalignment occurs when the axes of the two shafts are parallel but are offset laterally. A spacer coupling can handle parallel misalignment by virtue of its design. The spacer element (a cylindrical piece that connects the two coupling halves) provides the required lateral space between the shafts. This space allows the shafts to have a slight offset without inducing excessive stress on the machinery, thereby minimizing the risk of premature wear or failure.

3. Axial Misalignment: Axial misalignment occurs when the two shafts move closer together or farther apart along their axis. Some spacer couplings may have limited axial movement capabilities, which can help accommodate slight axial misalignment. However, it’s essential to ensure that the axial displacement is within the coupling’s specified limits to avoid overloading the coupling or the connected equipment.

Overall, spacer couplings are designed to be flexible and provide some degree of misalignment accommodation, but their ability to handle misalignment depends on their specific design and material properties. It’s essential to select the appropriate type and size of spacer coupling based on the expected misalignment and operational requirements of the machinery to ensure optimal performance and longevity of the coupling and the connected components.

editor by CX 2023-11-21

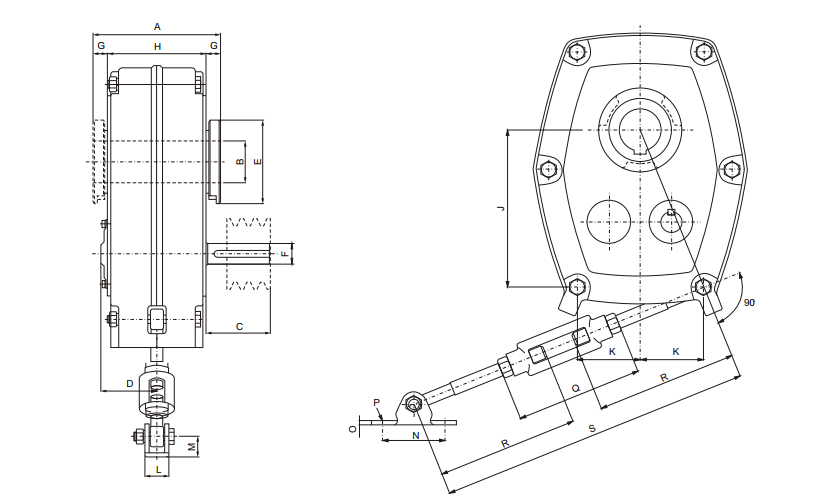

China cast iron worm gear reducer 22mm planetary gearbox coupling reducer 90 degree gearbox motor and gearbox boat coupling cast

Warranty: 1 a long time, 12months

Relevant Industries: Resorts, Garment Outlets, Developing Content Outlets, Producing Plant, Machinery Repair Shops, Foods & Beverage Manufacturing facility, Farms, Cafe, House Use, Retail, Foods Store, Printing Shops, Construction works , Energy & Mining, Foodstuff & Beverage Retailers, Advertising and marketing Business

Weight (KG): fifty eight

Custom-made assist: OEM, ODM, OBM

Gearing Arrangement: Helical

Output Torque: 800~100000N.m

Input Speed: 1400rpm

Output Velocity: fourteen-280rpm

Ratio: 7.5~100

Certification: ISO9001-2008

Mount Position: Foot Mounted

Bearing: LYC

Application: Packing Machine

Material: Cast Iron

Colour: Consumer Ask for

Heat therapy: High Frequency Quenching

Structures: Output Shafts

Packaging Particulars: Wooden containers , Cantons packed in 1 pallet

R sequence helical reducer gearbox for packaging machine do-it-yourself equipment reduction box electricity transmission gearbox 1) Output speed: .6~1,571r/min

2) Output torque: up to 18, High quality Supplier Tiny Processing Planetary Gear Set Steel Power Transmission Areas Ordinary Solution 1.5 Many years Small Gear .5 000N.m3) Motor energy: .18~160kW4) Mounted sort: foot-mounted and flange-mounted mounting

| Item Title | SLR Series Rigid Tooth helical reducer |

| Gear Materials | 20CrMnTi |

| Situation Content | HT250 |

| Shaft Material | 20CrMnTi |

| Equipment Processing | Grinding finish by HOFLER Grinding Equipment |

| Color | Personalized |

| Noise Take a look at | Bellow 65dB |

Packaging & ShippingPacking Specifics : Standard carton/Pallet/Regular wooden scenario

Shipping and delivery Information : 15-thirty operating times upon payment

Firm Details

Trade Demonstrates

Associated Product

Main merchandise list: sixteen collection which includes SLR/SLS/SLK/SLF collection difficult tooth flank gear reducer , SLRC collection aluminium scenario helical equipment reducers,SLHSLB collection substantial electricity speed reducer, SLP sequence planetary velocity reducer, X/B series cycloidal reducer, SLXG sequence shaft-mounted gear box, SLSWL collection worm screw jack, SLT series helical cone equipment box, entirely a lot more than 10,000 ratios, a variety of specification make us at the head of domestic transmission sector, extensively serve the mechanical transmission field of mild & heavy industry these kinds of as: beer & beverage, mining device, food packing, textile printing, rubber & plastic substance, petrochemical industry, FT804.40L.032 steering gear and valve block assembly, For CZPT Lovol Agricultural Real tractor Spare Elements jack-up transportation, pharmacy & method hides, environmental security tools.

FAQ1.Payment Expression: TT, L/C

two.Shipping time: about thirty times from obtain payment.

three.We acknowledge custom-made products as for each your unique prerequisite.

4.Xihu (West Lake) Dis.traces for the Assortment:Typically we can choose 1 equipment which is appropriate for you with some informations from you,this sort of as ratio/motor velocity/mounting dimension/ out torque and so forth.

five.If the minimum get sum is in excess of $10000, there are preferential.

Q1: What information should I inform you to confirm the product?

A:Design/Size, Transmission Ratio, Shaft directions & Order amount.

Q2: What can i do if I will not know which 1 I need?

A:Dont worry, Ship as a lot information as you can, our group will help you uncover the correct 1 you are looking for.

Q3: What is your solution warranty interval?

A:We provide 1 calendar year warranty considering that the vessel departure date left China.

This autumn: Are you buying and selling company or maker ?

A: We are manufacturing unit.

Q5: How prolonged is your shipping time?

A: Usually it is 5-10 times if the products are in stock. or it is 15-twenty times if the products are not in stock, it is according to quantity.

Q6: Do you offer samples ? is it totally free or added ?

A: Indeed, we could offer the sample for free cost but do not pay the value of freight.

Q7: What is your conditions of payment ?

A: Payment=1000USD, thirty% T/T in advance ,stability ahead of shippment.

If you have an additional query, pls come to feel cost-free to contact us as beneath:

Make contact with us

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by czh 2023-02-21

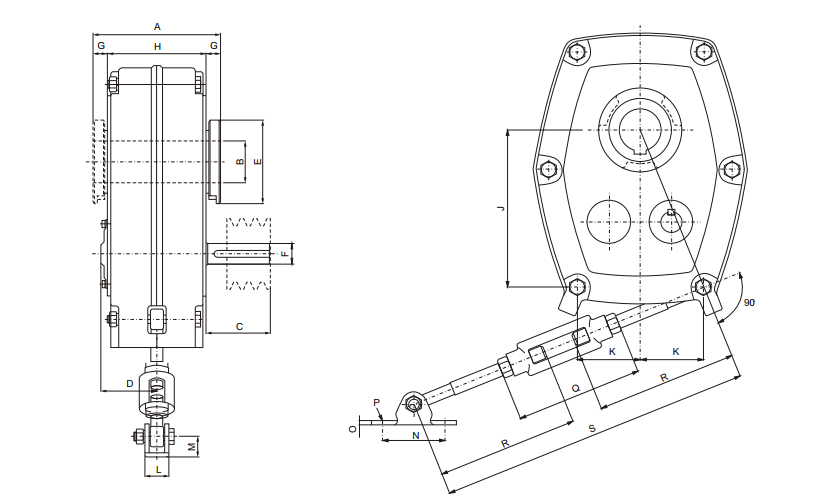

Best China manufacturer & factory TXT in Vientiane Lao People’s Democratic Republic Type Gearbox Conveyor Gear box manufacturer With high quality best price

Full use has been created of all kinds of superior methods and engineering to attain excelsior production.

Overview

Swift Specifics

- Relevant Industries:

-

Building Content Stores, Production Plant, Equipment Repair Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

two.68-134.2N.m

- Input Velocity:

-

1440rpm

- Output Pace:

-

10-407rpm

A PTO shaft transfers the electrical power from the tractor to the PTO powered attachment. This permits the tractor to power a assortment of tractor implements which includes flail mowers, wooden chippers, rotary tillers, excavators, and more.

- Area of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Product Amount:

-

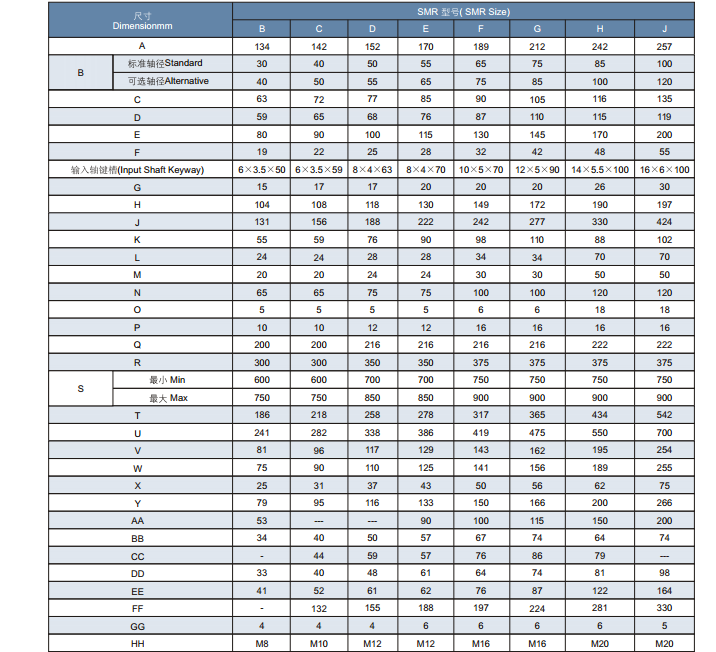

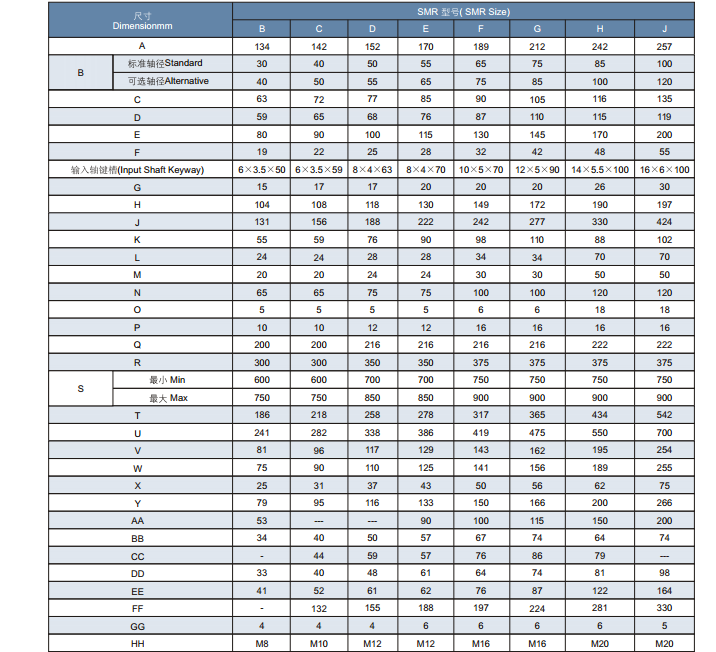

SMR

- Rated Energy:

-

two-130KW

- Item Name:

-

TXT Variety Gearbox Conveyor Equipment box producer

- Answer:

-

Mining, Belt Travel, Conveyor

- Size:

-

B-J

- Lubrication:

-

Artificial Oil, Mineral Oil

- Warranty:

-

twelve Months

- Certificate:

-

CE ISO9001

The centering device is part of the worm-gear assembly line. An operator loads the reducer housing and bearing include, and the device decides the spacing among output bearing seats.

Supply Capability

- Source Capacity:

- 200000 Piece/Pieces for each 12 months

Our goods are selling well in Chinese markets and some goods marketed in international marketplaces are effectively obtained by Chinese and overseas customers at home and overseas.

Packaging & Supply

- Packaging Particulars

- Common export packing and wood pallet packing

- Port

- Shanghai or Ningbo Port

On-line Customization

Comprehensive Images

Pictures of TXT Sort Gearbox Conveyor Gear box manufacturer

Packing & Shipping and delivery

Packing Photographs of TXT Sort Gearbox Conveyor Equipment box maker

Interior Packing: PP bag with carton

Outer Packing: Wooden circumstance

Cargo: 14-20 days upon receiving the deposit.

Relevant Merchandise

SEW Sort Gearbox with Motor

FR Helical Gearbox with Motor

Forged Iron Worm Gearbox

NMRV Worm Gearbox

SMR Shaft Mounted Gearbox

Dodge TXT Type Shaft Mounted Gearbox

About Us

At any time_electricity Group is the first and biggest worm gearbox maker in China, recognized in 1976, specialising in the generation of a extensive variety of transmission equipment. With a lot more than 40 many years experience in the business, our belongings now whole 117.2 million pounds, and we have 2 subsidiary businesses, 8 holding organizations, and twelve joint-stock companies.

We can generate 400,000 units of worm gearboxes, one hundred,000 units of gear reducers, 50,000 units of other velocity reducers, a hundred and fifty,000 units of flexible couplings, and one hundred,000 units of pace-reducer equipment each and every calendar year.

70% of our products have been exported to forty a lot more nations, and our consumers arrive from Italy, Germany, United states of america, Canada, Spain, United kingdom, India, Mexico, Brazil, Argentina, Turkey, Singapore and other principal industrial nations. 30% of them are OEM made for immediate producers of other goods.

FAQ

Q1. Is your top quality very good?

A1: Quality in no way notify lies, we’re the largest maker and exporter of worm gear reducer in Asia, the very first reducers and gearboxes company in China, who has been given license given that 1993. Also, we had achieved ISO9001 and CE Certification between all companies.

Q2. How is your price tag? Can you offer any low cost?

A2: We will give the best value we can base on your requirements and the portions.

Q3. Do you provide any visiting?

A3: Yes! We sincerely invite you to pay a visit to us! We can pick you from airport, railway station and so on. Also, we can set up housing for you. Please enable us know in superior.

This fall. When is the ideal time to contact you?

A4: You can get in touch with us by email any time, we will reply you ASAP. If you want make contact with by telephone, our doing work hour is Mon-Sat 9am-seventeen:30pm.

Speak to

At any time_electrical power Group

Address: No.789-B8Shenhua Street, XiHu Dsitriction Enco&Tech Growth Zone HangZhou Metropolis, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Web site: www.hzpt.com